Customer's inspiration

The picture our customer gave us for inspiration.

I may be biased, but I think we improved on the design by removing the moldings that (I believe) were added to hide the transitiion from the arch to the bottom section, and adding the functionality of working doors and drawers on the columns, and innovative lighting with the Tresco NeoLoop.

And did I mention the customer calls it THE Bar? I can't think of a higher form of praise. For me, hearing him say that makes it all worthwile.

The arches

Designed in CAD and cut on our CNC. The parts are coming together. The channels for the Tresco Neoloop LED's are visible on the side panels.

Access for the lighting via cutouts on the arch sides -the top section of the column will have a working door to allow access for mounting power supplies and wire access.

The middle arch was too big to cut in one piece, we used dog-bone joinery to bring the sides together.

The columns.

The columns are laid out next to the arches , not because we wanted to confirm the sizing -we were just excited to see them coming together. The columns are Wilsonart Interiors Crisp Linen.

Blum hinge plates and undermount softclose glides are preinstalled.

5 minutes after delivery.

The columns were delivered before the arches so the contractor could get the necessary countertop installed. The arches were delivered and lifted into place literally within 5 minutes of being delivered.

The completed arches have hardwood nosing on the inner edges to prevent dents or dings from slinging liquor bottles around.

The extra space on top of the columns are for making the attachment of crown molding easier.

Perfect fit.

There are always unknowns when designing and manufacturing cabinets for any space, but when doing something unique there is definitely a sigh of relief when you see it coming together without any "Oh shi-!" moments.

The Wilsonart Interiors Linen used on the columns is double sided thermally fused laminate -we laid up the sides with raw maple to allow for paint. The edgeband is also paintable raw maple.

Primer going on.

The custom arch moldings are ValuFlex from Hudson & West. This is really a cool product -paintable and stainable, and custom formed to our specifications. The curved top section is mated to straight MDF molding sections that meet seamlessly.

Tresco NeoLoop channel.

The curved sections of the arch are kerf cut MDF with a maple veneer. We didn't make all of those kerf cuts -it's now an off-the-shelf product.

However, we did have to figure out how to make the Tresco NeoLoop channel work without compromising the stability of the acrh. The solution was to make the arch in two sections -it wasn't the easy way, but it was the best way.

The ValuFlex molding fits perfectly with a tiny reveal of the hardwood nosing.

More molding.

Who doesn't want to see more of that curved molding? Plus the stacked crown that really anchors the arch and column section.

Tresco NeoLoop LED's

I was personally very excited to use the NeoLoop for the first time. When discussing the project our engineer didn't like the idea -and even liked it worse when he realized we needed to make six kerf cut arches instead of three to properly seat the led channel. Very happy we persisted and made the unique arch lighting a reality.

There was an "Oh Shi-!" moment when the supplier we ordered a custom curved door panel for the island informed us six weeks after accepting the order -that they couldn't deliver...like ever, as in never. Luckily the installation crew came through with a quick solution. Not ideal, certainly not our design -but sometimes things happen that you cannot control.

Form and Function.

The columns feature working doors and a single drawer above the counter top -why waste storage space? The taller top doors open to allow access for the sconces and LED wiring.

Matching end panels are the only proper way to finish the exposed side of the first column. Matching the panels to the adjacent doors is a subtle way of expressing your attention to detal.

The business side of the bar.

The bar sink is on the wall side with an ice-sink on it's right. A Kessebohmer Dual 52 quart trash pullout keeps things tidy. The undercounter refrigerators are surrounded by easy access open-shelf cabinets. A large storage cabinet on the end sets the bar-height and encloses the workspace.

Oh did I forget to mention the wine cellar?

Credit where credit is due. This project came together through the hard work of Darell Roush Design/Build of Anaheim, the contractor for the project, and his hard working crew of installers led by Alex Salgadomondrago.

Glamour shot.

We had nothing to do with the in-ground wine cellar dug right into the living room floor by Darrell Roush's company. But we just had to share this beauty.

Yeah, we did their closet too...

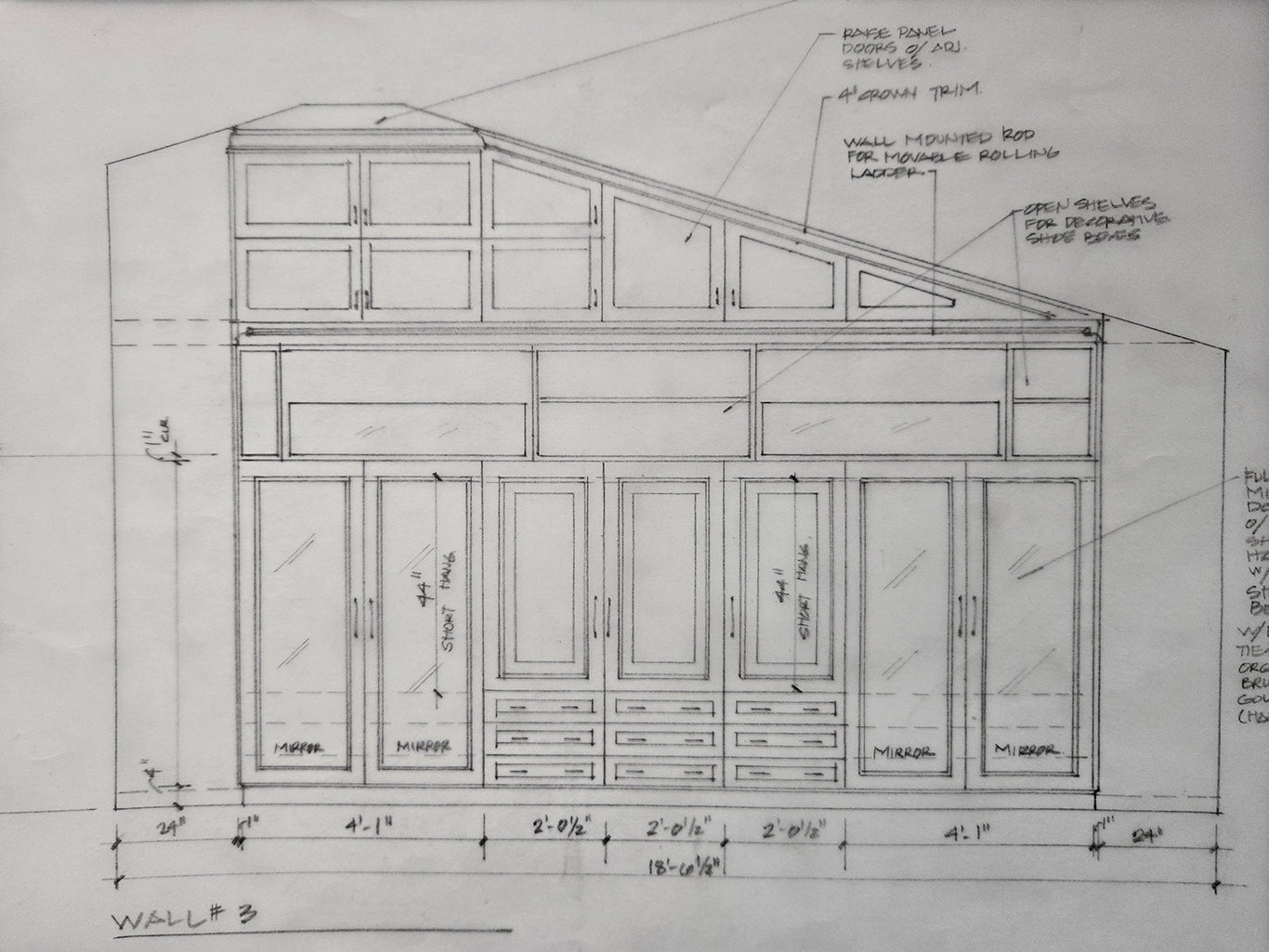

The original design (by Vicki Bush & US RTA CAB

INETS). One of four walls in this epic two-story closet. We are finishing up work on the custom Library Ladder and will bring you this post when it is complete!